|

Idyllic FS 2-1100 flexographic press with printing width 1100 mm successfully works in-line with an extrusion laminator at a customer' site.

|

Stack-Type Flexographic Printing Presses

Idyllic FS flexographic presses are designed for printing simple jobs, such as solids and multi-color images with low screen ruling on a broad range of packaging products, such as film for bags, gift package, wrapping paper, milk package, cardboard package, etc. Idyllic FS presses are simpler and cheaper than central impression drum Idyllic FP presses, even though they use the same engineering solutions as CI-drum press. Idyllic FS presses can print on PE, PP films, paper and cardboard, and laminated substrates up to 350 micron. Reliability, printing consistency, high quality parts, simple design and ease of use are among their major advantages.

Printing Unit and Color Stations

Side frames and the bottom frame of the press are made of 60 mm heavy-duty structural steel to ensure vibration-free operation at any printing speed. In order to prevent ink from drying during machine stoppage, anilox rollers continue to rotate driven by separate electric motors.

Plate and anilox rollers are driven through steel helical gears.

Plate and anilox rollers mounting supports are fixed and moved in precision linear guides.

Color stations are equipped with highly efficient chambered doctor blade systems.

Doctor blade change is very easy and its complete disassembly takes a minimum of time, due to original quick fixation systems of supports and rollers.

Color stations are equipped with pneumatic membrane ink pumps.

Idyllic FS is equipped with efficient printing pressure, lateral and circumferential register control systems, similar to those used on central impression drum Idyllic FP presses.

Unwind and Rewind Unit

Presses are equipped with single-shaft unwind and rewind units. To reduce roll change time, it is possible to install a second shaft.

Idyllic FS presses feature an automatic tension control system with a dancer roller and a powder brake.

As option, it is possible to assemble automatic web guide system on unwinder and corona web treatment system.

Drying system

Idyllic FS presses feature hot air drying units with electric heating.

Dryers installed after each color station do primary ink drying. A finishing dryer installed on the connecting bridge performs final drying. The dryers are designed to ensure effective ink drying at any printing speed.

Digital Press Control System

The press is equipped with a digital control system with programmable logic controller (PLC). All main control functions are performed via the main control panel.

Setting and displaying of current working parameters is carried out via color touch-screen display. All information is displayed in the English language.

The press features a remote service control system. The system facilitates remote Internet or phone modem connection with the Idyllic service center for remote diagnostics and even elimination of problems on the press located at the customer's site. The press features self-diagnostics and operator error-proof systems.

The control panel is used to actuate the following functions:

- start/stop of the entire press or its separate units;

- selection of working modes;

- adjustment of press operation speed;

- setting a dryer's temperature and air velocity;

- switching on/off of color stations;

- switching on/off of unwind/rewind shafts;

The display shows the main parameters of press performance:

- web speed information;

- meter/job counter;

- self-diagnostics system messages;

- operator prompts.

Idyllic FS Technical Characteristics

| Number of Color Stations |

2-4-6-8 |

| Max. Operation Speed |

250 m/min |

| Max. Web Width |

600 - 2100 mm |

| Print Repeat |

300 - 1000 mm |

| Max. Unwind/Rewind Diameter |

600 mm |

| Tension Range |

2 - 50 kg |

| Register Accuracy |

± 0,5 mm |

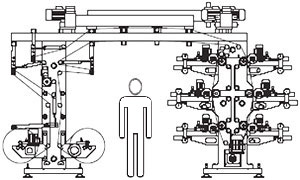

Layout of stack-type flexopress Idyllic FS 6

|