Gravure printing presses

Gravure printing presses Idyllic RS - are up-to-date development of Idyllic Company and are designed for high-quality printing on flexible packaging substrates - thin plastic films: BOPP, LDPE, LLDPE, PP, PET, PVC, metallized film, coextruded films, as well as aluminum and backed foil, plastic films (BOPP, LDPE, LLDPE, Cast PP, PET), coextruded films, laminated materials, paper and cardboard.

First of all, Idyllic RS series presses are notable for high degree of automation. Idyllic RS are equipped with gearless drive, job quick-change system on the basis of sliding color stations, have previously printed circulation parameters storage function for rerun, can be equipped with automatic printing pressure adjustment systems and automatic registration, counterpressure cylinder automatic preset system, non-stop systems on unwinding and rewinding units. Idyllic RS are equipped with self-diagnostic systems, remote service control through modem, order, etc.

High rate of productivity, reliability and effectiveness of Idyllic RS press are achieved by its designers due to application of all modern developments in the field of gravure printing.

Unwinding unit

Unwinding unit is made of solid frame with steel walls of 40 mm thickness. Unwinding unit is equipped with one shaft for reel mounting and automatic tension control system by dancing rollers and powder brake clutch. As option, it is possible to assemble automatic web guide system on unwinder and corona web treatment system. For easy mounting and taking down of reels, unwinding unit is equipped with electromechanical lifting device.

Printing unit

Printing unit is made of solid frame with steel walls of 50 mm thickness. For easy maintenance, ink units are made retractable. Plate cylinder drive is synchronized with the press operation and is carried out through spline coupling from main motor. Printing unit has its own automatic web tension control system. Ink fountain is made of stainless steel. Optionally Idyllic RS can be equipped with automatic register system reading printed register marks on the web and video control system to control printing quality.

Intersection tunnel dryer

Drying unit dries printed image by means of hot air blasting. Preset air temperature is automatically controlled, and an operator, depending on the job, adjusts air quantity fed by fans. Dryer can be either single-chamber or dual-chamber, depending on customer tasks and required maximum printing speed.

Rewinding unit

Web rewinding unit design is similar to that of unwinding unit, it has one shaft, automatic web tension control system, and electromechanical lifting device to mount and take down reels. Optionally Idyllic RS can be equipped with automatic web guide system on rewinder.

Control system

Idyllic RS presses are equipped with digital control system with programmable logic controller (PLC). Main control functions are made by means of a control panel with color touch LCD display having english interface. Unwinding and rewinding units are equipped with control panels for mounting and taking down reels.

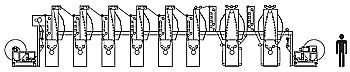

Layout of Gravure printing presses Idyllic RS 8

|